Geyserwise PV Solar Geyser Conversion Kit 200L (Excluding Panels And Mountings)

R9,574.99 inc.

In 2010 Geyserwise won the residential category in the prestigious ETA Awards, an Eskom sponsored initiative to reward Energy Efficiency. “A distinct feature of the Geyserwise product is the increased level of awareness of energy efficiency and behaviour change among the users.

Description

Geyserwise has developed a revolutionary solar geyser system that is not only more efficient than conventional solar geysers but can be installed in less than half the time it would take to install a split pumped solar system with a traditional flat plate or evacuated tubes collector. Also, the initial capital layout is less than half that of a conventional solar geyser.

This system uses a PTC (Positive Temperature Co-efficient) dual AC and DC Stainless steel element expected to last in the region of 10 years. It has been proven that even with the AC back upon, this element is up to 30% more efficient than an electric immersion heating element.

This system makes for easy conversion of literally any existing electrical geyser out there, to solar. It uses PV technology with the use of a specifically designed MPPT (maximum power point tracker) to maximize the output of your PV panels/solar panels to the element.

Real-time system performance is monitored on the system controller display which can be installed anywhere in your home that suits your needs, from this controller you can set the AC backup timer, set the maximum water temperatures and set your geyser to holiday mode if you will be away for a couple of days.

One of the most important factors consumers can benefit from include that the installation of this system does not void your geyser warranties by the manufacturer. The system has been approved by the likes of Kwikot, Heat Tech, Duratherm, and many more. It might be equally important to note that this system is SABS approved.

The SABS certificate and letters from other geyser manufacturers can be downloaded from the specifications tab.

There are kits available from 100Litres to 200Litres with both AC & DC Power supply. However, for 50Litre geysers, the standard dual function element does not fit inside the geyser and therefore only the 1100w DC Element can be installed on these geysers. (See this element in the “accessories” tab. Or click here.

Below is a list of all the components typically included with a kit, we provide the option to buy these kits with no panels.

(Please note that the system has to be independently connected to the number of panels as outlined per kit below.*)

Important Note: Roof Hook Brackets not included (this is required for tile roof installations) – see Accessories Tab

Typical Tile roof hook bracket installation

- 100L PV Kits – 4 roof hook mounts required*

- 150L PV Kits – 6 roof hook mounts required*

- 200L PV Kits – 8 roof hook mounts required*

The 200L Kit is made up of the following components

| 2 kW AC/DC Withdrawable Element |

| Flange if required (Flange is used on Heat Tech and Kwikott Geysers) |

| PTC Stainless Steel Sensor Tube |

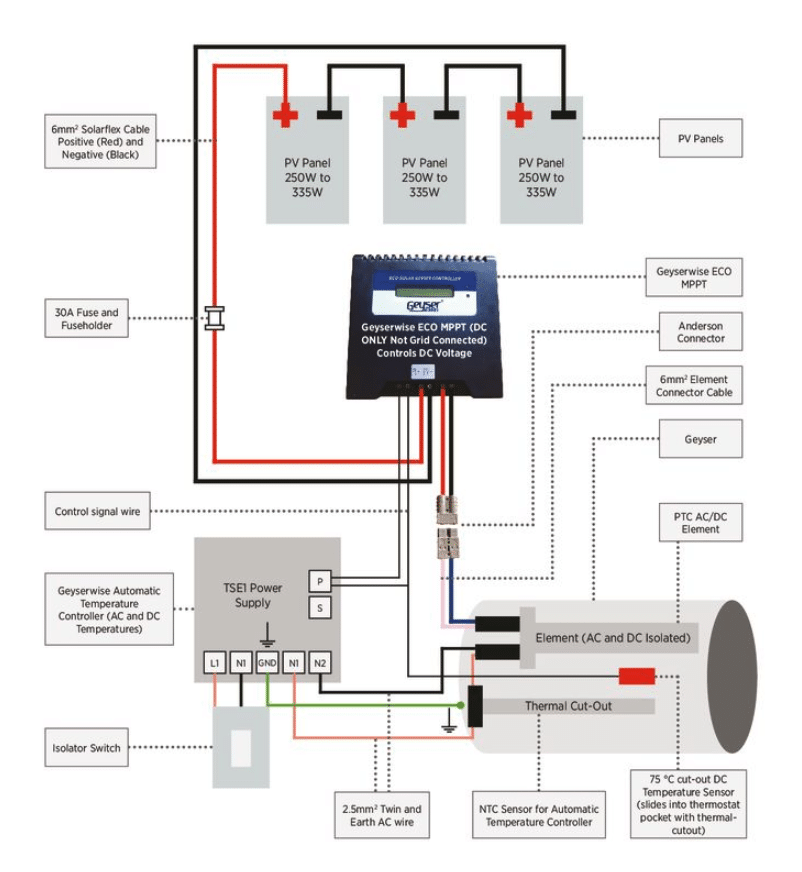

| ECO MPPT |

| TSE1 Controller |

| Inline Fuse holder |

| 30A Fuse |

| Element Connector Cable |

| Anderson Connector |

| Pig tail |

Watch: PV System Installation video

Note from the Manufacturer

- It is important to understand the limitations of the MPPT and the size and amount of PV panels that can be connected to the MPPT

- Limitation 1: Input voltage of 138 VOC (on average) Maximum 150 VOC

- 3X270W PV Panels in Series = 38.7 VOC X3 = 116.1 (well withing the voltage specified)

- 3X330W PV Panels in Series = 138.6 VOC X3 = 138.6 (this is also fine for average operation)

- 3 LARGER PANELS OR HIGH VOLTAGE PANELS SHOULD NOT BE CONNECTED IN SERIES

- ALL OUR DIAGRAMMES SPECIFY THE HIGHEST SIZE AS 335W AND INSTALLERS SHOULD STICK TO THIS

- IF MORE PANELS ARE REQUIRED THE PANELS CAN BE PUT 2 in SERIES, 2 in SERIES THEN PARALLEL. BUT REMEMBER THERE ARE LIMITATIONS ON THE OUTPUT AMPERE AS WELL, SO THE VOLTAGE ALONE SHOULD NOT BE USED TO MAKE THE CALCULATION. THE OUTPUT AMPERE SHOULD BE TAKEN INTO ACCOUNT AS WELL.

- Limitation 1: Input voltage of 138 VOC (on average) Maximum 150 VOC

-

- Limitation 2: the load: The element is only rated at 900W on average (MAXIMUM 1200W). Any excess energy connected to the MPPT cannot be used by the load. The MPPT would have to get rid of this energy somehow. For example, if 1600W is connected to the MPPT and PV panels are producing 1600W, but the element can only use 1200W of energy. Somehow the MPPT would need to absorb an extra 400W.

- Consequence: MPPT will run at higher temperatures than it should

- Components will be put under severe

- It is important to stick to the Maximum 1200W PV Panels to be connected to the MPPT

- PLEASE MAKE ALL INSTALLERS AWARE OF THIS AS MANY INSTALLERS ARE CONNECTED TOO MANY PANELS (IN TERMS OF TOTAL WATTAGE) TO THE SYSTEM AND NEITHER THE MPPT NOR ELEMENT IS DESIGNED FOR THIS. IT IS NOT APPROPRIATE TO CONNECT 4x410W PANELS ON THE SYSTEM. IT DOES NOT MATTER IN WHAT CONFIGURATIONS YOU CONNECT THE PV PANELS

- OUR DIAGRAMMES ARE VERY CLEAR ON WHAT COMBINATIONS OF PV PANELS ARE ALLOWED

- WITH ANY RETURNS – PLEASE CONFIRM THE CONFIGURATION AND AMOUNT OF PV PANELS – WE WILL NOT EXCHANGE UNITS THAT HAVE NOT BEEN CONNECTED PROPERLY.

- We can try and repair these units, but the same will happen again if the number of PV panels are not reduced

- Limitation 2: the load: The element is only rated at 900W on average (MAXIMUM 1200W). Any excess energy connected to the MPPT cannot be used by the load. The MPPT would have to get rid of this energy somehow. For example, if 1600W is connected to the MPPT and PV panels are producing 1600W, but the element can only use 1200W of energy. Somehow the MPPT would need to absorb an extra 400W.

-

- Limitation 3: Maximum output Amps: 25A (per attached sheet)

It is important to understand that if the PV panels are connected in parallel that the input Current increases (compared to the series connection). For example, two series, so series then parallel on 270W or 330W PV panels will give you an input current in the region of 16A to 18 A. For a series connection, the input current will be in the region of 8A and 9A for 270 W PV panels and 330W PV Panels.

As per the picture below, the job of the MPPT is to ensure that the output voltage matches the load voltage. In our case, the load voltage is between 48V and 72V. If the voltage is reduced, the output current must increase.

When panels are connected in series, the risk remains low that the output current will exceed the 25A as per our specifications. When panels are connected in parallel, the risk of exceeding this output current increases and it is VERY important not to connect PV panels that have an Imp exceeding 9A. This gives the MPPT enough space to stay within the 25A output current. If larger-sized panels are used (above our specifications) this output current will be exceeded and will most probably lead to failure on some components on the MPPT.

Important Notice: Livestainable relies on the relevant suppliers/manufacturers and/or third-party sellers to provide adequate information displayed on the products we promote on Livestainable.co.za. Therefore, in some cases Errors and Omissions could be expected.

Noticed incorrect information or an issue with this page? Let us know

Additional information

| Weight | 12 kg |

|---|---|

| Shipping Dimensions | L 60 × W 40 × H 20 (cm) |

| Brand | |

| Warranty | 12 Months Extendable to 3 years *Fill out the below form to extend your warranty |

| Brand | Geyserwise |

| SKU | 200LPVKITNPM |

| CATEGORY | Geyser Conversions, Complete Kits |

| TAGS | Geyserwise |

in stock

in stock